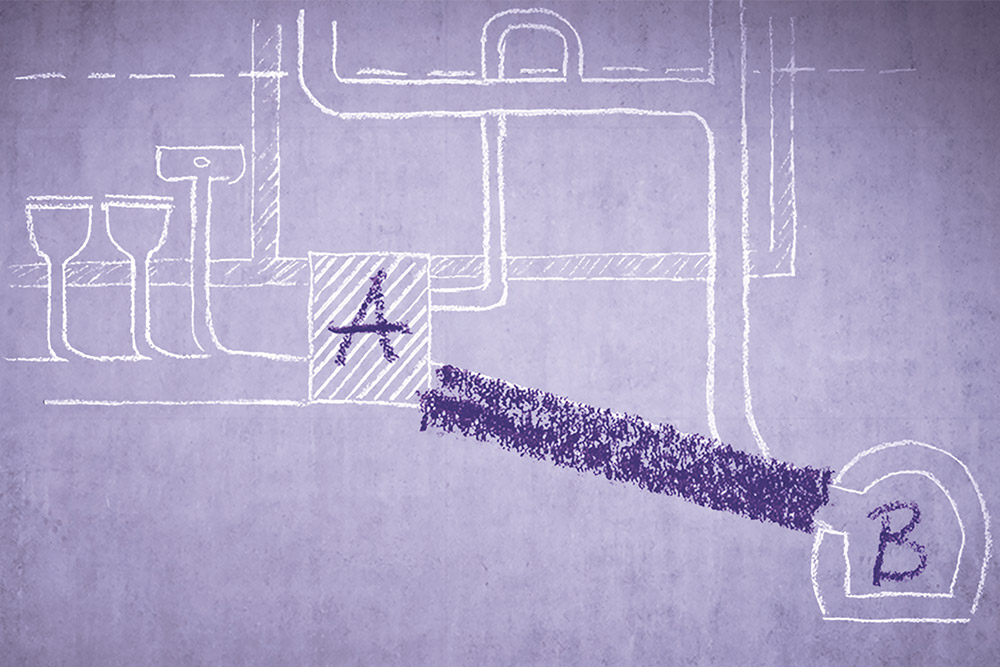

With the Ecolift XL, KESSEL AG is now also supplying a hybrid lifting station for use in commercial buildings and multi-family homes. “So far, Ecolift could only be installed in single-family homes. The new XL version can also cope with large amounts of wastewater,” explains Lars Weißmann, head of Product Management at KESSEL AG. The advantage the hybrid lifting station has over traditional lifting stations is that Ecolift XL uses the efficiency of natural gradient during normal operation (no backwater or flooding) – the Ecolift XL only uses its pumps during times of backwater or flooding, pumping the building’s wastewater via a bypass directly into the surcharged sewer pipe. “The fact that the pump only runs when there is backwater from the sewer not only saves operator’s energy costs, it also significantly cuts maintenance costs,” Weißmann adds.

Reliable operation

In the event of backwater, the motor-driven backwater flaps of the new hybrid lifting station close and provide maximum flood protection to the building. The pneumatic level sensor assures accurate pump operation and the alarm sensor provides an additional back-up alarm. The pressure pipe outlet has been designed for nominal size 80, inlet and outlet are suitable for pipes up to nominal size 150. Ecolift XL is available with pumping capacities of 1.5 kilowatt to 4.5 kilowatt. In addition, KESSEL also offers solutions tailor-made to customer requirements. The hybrid lifting station can be used as a free-standing set-up connected directly to the outlet of a grease separator for example, or can be installed in an existing concrete pit using the respective KESSEL system components.

Low-noise operation

“Despite the mechanical design and insulation of traditional lifting stations they are still a constant source of noise since every liter of a building’s wastewater needs to be pumped out – regardless if there is backwater or not. In contrast, the Ecolift XL uses the natural gradient to drain waste from the building (without any pumps activating) and only activates the pumps during backwater. This means that pumping operation noise only occurs in exceptional cases,” Weißmann explains. This is an advantage not only for apartment blocks with basement apartments, but also for commercially or public used buildings such as offices, schools, hospitals and residential homes for the elderly.

Installation in an inspection chamber also possible

Ecolift XL is integrated in a newly designed, high-quality, standard-compliant polymer inspection chamber which is suitable both for installation in the ground or in concrete. “The chamber is resistant to groundwater up to 3 metres and can be built up to a height of five metres. The light weight of the polymer chamber makes it particularly easy to install,” Weißmann explains. The chamber is available with an access opening of 600 millimetres in diameter and now also in a new version with a diameter of 800 millimetres.